Specification

- தயாரிப்பு படிவம்

- Pipe

- பொருள் இயைபு%

- Ni: 30-35%, Cr: 19-23%, Fe: ≥ 39.5%

- வெப்ப எதிர்ப்பு

- Yes

- அரிப்பை எதிர்க்கும்

- Excellent

- இழுவிசை வலிமை

- 600 MPa min

- மறுசுழற்சி

- Yes

- விட்டம்

- 6 mm to 219 mm

- கடினத்தன்மை

- ≤ 170 HB

- அளவு

- Standard and custom lengths available

- பூச்சு வகை

- Uncoated / Plain

- தயாரிப்பு பெயர்

- எஃகு வகை

- எஃகு தயாரிப்பு வகை

- தரம்

- Inconel 800 (UNS N08800)

- தடிமன்

- 1.0 mm to 12 mm

- வடிவம்

- ஸ்டீல் ஸ்டாண்டர்ட்

- பரப்பு

- Polished

- இயைபு

- 32% Ni, 21% Cr, balance Fe

- விண்ணப்பம்

- எடை

- Depends on size and thickness

- கலர்

- Silver

- பொருண்மைத் தரம்

- Inconel 800

- பினிஷ் வகை

- Annealed / Polished

- பயன்பாடு

- High temperature & corrosion-resistant environments

- Elongation

- 30% min

- End Connection

- Plain, Beveled, Threaded

- Melting Point

- 1357°C - 1385°C

- Pressure Rating

- Up to SCH XXS, based on wall thickness

- Testing

- Ultrasonic, Hydrostatic, Eddy Current

- Yield Strength

- 205 MPa min

- Manufacturing Method

- Seamless / Welded

- Standards Compliance

- ASTM B407, ASTM B514, EN 10216-5

- Weldability

- Excellent with appropriate filler metals

- Service Temperature Range

- Up to 1100°C continuous

- Density

- 7.94 g/cm³

Trade Information

- Minimum Order Quantity

- 5 Kilograms

- வழங்கல் திறன்

- வாரத்திற்கு

- டெலிவரி நேரம்

- நாட்கள்

About

Highly Recommended for valiant performance in extreme conditions, the Inconel 800 Pipe stands as a best-seller among Nickel-Iron-Chromium alloy pipes. Get It Now to experience exquisite heat and corrosion resistance, suitable for continuous temperatures up to 1100C. With a venerable compliance to ASTM B407, ASTM B514, EN 10216-5 standards and available in custom dimensions, this pipe offers exceptional tensile strength (600 MPa) and elongation (30%). Ideal for use in construction, power generation, and chemical processing, it comes with excellent weldability and undergoes ultrasonic, hydrostatic, and eddy current testing for flawless integrity.

Broad Utility of Inconel 800 Pipe: Usage & Applications

Inconel 800 Pipe is utilized in a range of high-temperature and corrosion-resistant environments, making it ideal for construction, petrochemical plants, and power generation applications. Frequently used for heat exchangers, furnace components, and chemical processing equipment, its robust mechanical properties ensure reliability and longevity. The pipe is suited for usage in severe service conditions, supporting both standard and custom requirements across industries seeking dependable performance and durability in demanding operations.

Certifications & Export Markets for Inconel 800 Pipe

Every Inconel 800 Pipe is stringently tested and certified as per ASTM B407, ASME SB407, and EN standards. Serving a wide Main Domestic Market across India, order processing is seamless and systematic. Main Export Markets include the Middle East, Europe, and Southeast Asia. Each order undergoes careful order completion, precise packing, and timely dispatch, ensuring products reach customers intact and ready for high-performance applications wherever required globally.

Broad Utility of Inconel 800 Pipe: Usage & Applications

Inconel 800 Pipe is utilized in a range of high-temperature and corrosion-resistant environments, making it ideal for construction, petrochemical plants, and power generation applications. Frequently used for heat exchangers, furnace components, and chemical processing equipment, its robust mechanical properties ensure reliability and longevity. The pipe is suited for usage in severe service conditions, supporting both standard and custom requirements across industries seeking dependable performance and durability in demanding operations.

Certifications & Export Markets for Inconel 800 Pipe

Every Inconel 800 Pipe is stringently tested and certified as per ASTM B407, ASME SB407, and EN standards. Serving a wide Main Domestic Market across India, order processing is seamless and systematic. Main Export Markets include the Middle East, Europe, and Southeast Asia. Each order undergoes careful order completion, precise packing, and timely dispatch, ensuring products reach customers intact and ready for high-performance applications wherever required globally.

FAQ's of Inconel 800 Pipe:

Q: How can Inconel 800 Pipe benefit industries operating at high temperatures?

A: Inconel 800 Pipe is engineered for outstanding heat resistance up to 1100C, making it an excellent choice for industries such as petrochemical, power generation, and chemical processing, where prolonged high-temperature service is crucial.Q: What standards does the Inconel 800 Pipe comply with?

A: The Inconel 800 Pipe adheres to ASTM B407, ASTM B514, EN 10216-5, and ASME SB407 standards, ensuring consistent quality and reliability in a range of industrial applications.Q: Where is the Inconel 800 Pipe commonly used?

A: This pipe is commonly used in construction, furnace equipment, heat exchangers, and in environments requiring strong corrosion and oxidation resistance under high temperature conditions.Q: How is order processing handled for domestic and export markets?

A: Orders are carefully processed, thoroughly checked, and efficiently packaged for both domestic (India) and international markets, with dispatch coordinated to ensure timely delivery and product integrity.Q: What testing methods are applied to ensure the quality of Inconel 800 Pipe?

A: Each pipe undergoes ultrasonic, hydrostatic, and eddy current testing to guarantee its structural integrity and flawless performance under demanding operational scenarios.

Price 2000 INR/ Kilograms

- Minimum Order Quantity

- Supply Ability

- Delivery Time

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

கைபேசி number

Email

மேலும் Products in இன்கோனல் தயாரிப்புகள் Category

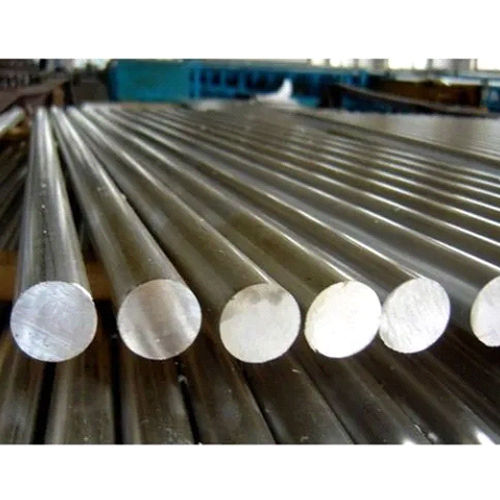

நிக்கல் அலாய் பார்

பரப்பு : மெருகூட்டப்பட்டது

விலை அலகு : கிலோகிராம்/கில

குறைந்தபட்ச ஆர்டர் அளவு : 5

அளவின் அலகு : கிலோகிராம்/கில

விண்ணப்பம் : கட்டுமானம்

விலை அல்லது விலை வரம்பு : ரூபாய்

விசாரணையை அனுப்பு

விசாரணையை அனுப்பு எஸ்எம்எஸ் அனுப்பவும்

எஸ்எம்எஸ் அனுப்பவும்